MOSW-O®

Air Electrolysis – Saline Electrolysis

Leaders in innovation in the industry of oxidant generators in situ for the disinfection of water through Electrolysis, our systems combine air, water and electricity in the case of air electrolysis, and salt, water and electricity in the case of saline electrolysis . In both cases, the result is the generation of highly effective In-Situ disinfectants at a very competitive cost. The design of our technology gives its users the necessary freedom to produce disinfectants in the quantity they require, when they need it. MOSW-O® reduces and eliminates hazardous by-products and water contaminants. Using only elements present in nature in a sustainable way, our technology generates an advanced disinfectant in situ at the point of use. A clean and environmentally neutral technology.

AEREAL ELECTROLYSIS & SALINE ELECTROLYSIS

Energy Consumption

Reduction of Energy Consumption

Less Containers

Eliminates Non-Reusable Chemical Containers

Transportation Reduction

Reduces transport and carbon footprint by 80%

Less CO2

Reduction of CO2 Emissions

Avoid storage

Eliminates storage of dangerous products

Plug & Play

Does not require reports given its low concentration

Low maintenance

Simple Operation and Maintenance

Without residues

No precursors or hazardous waste are generated

Air + Water + Electricity = H2O2

RELIABLE AND EFFECTIVE TO ANY CHALLENGE

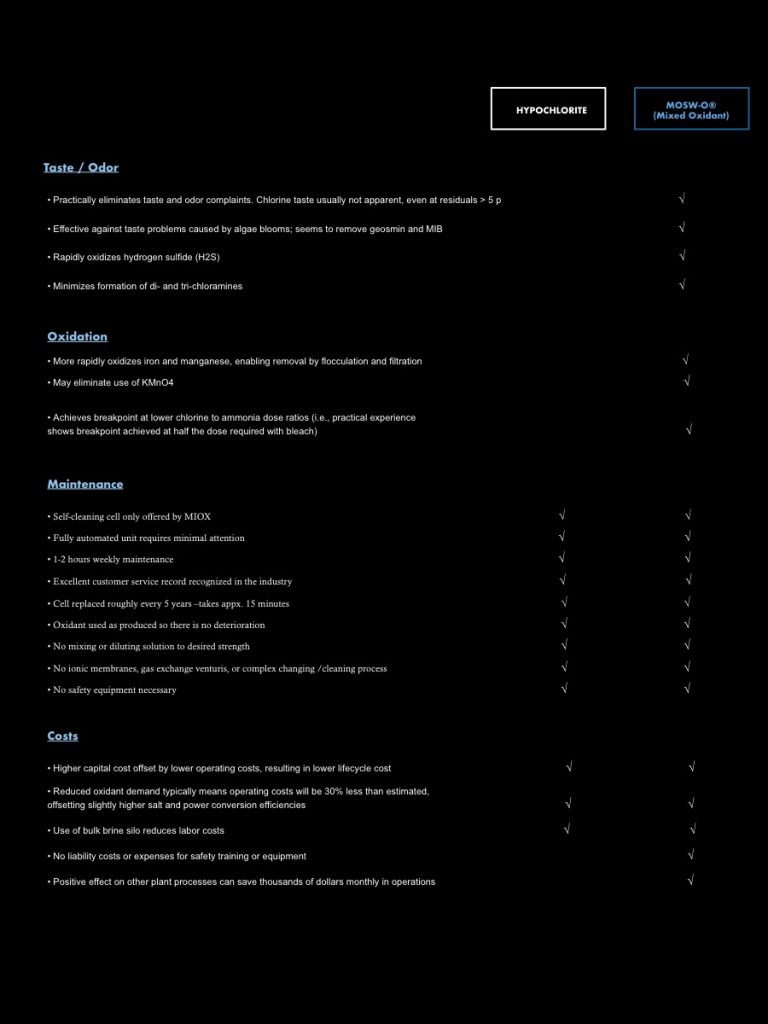

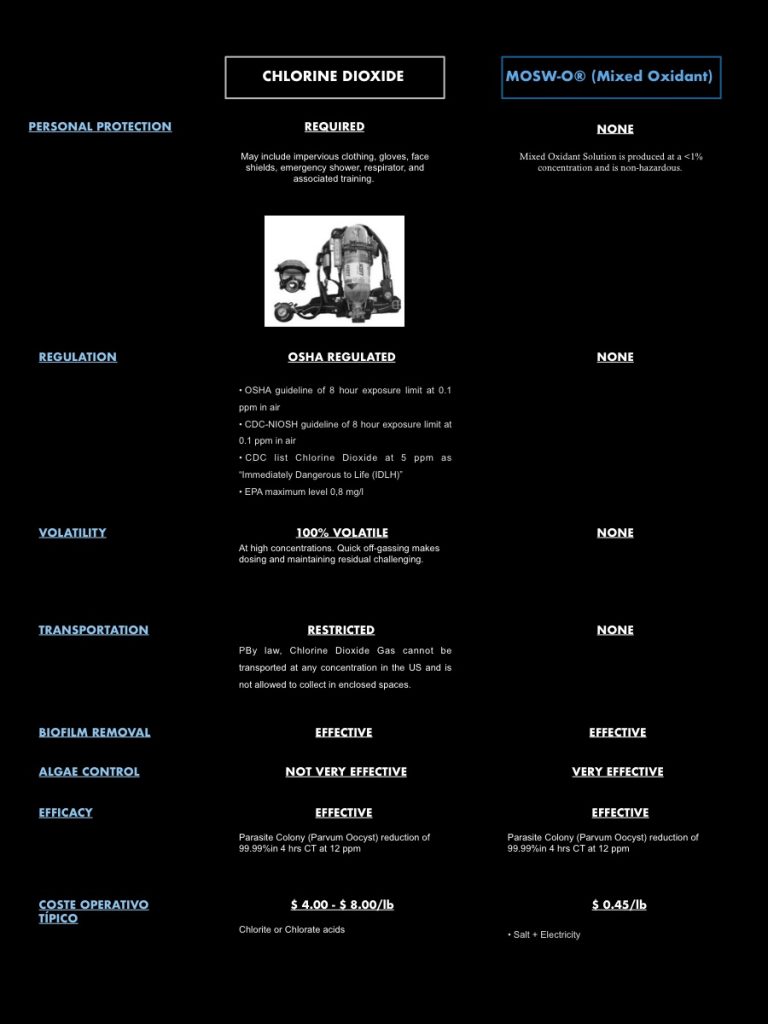

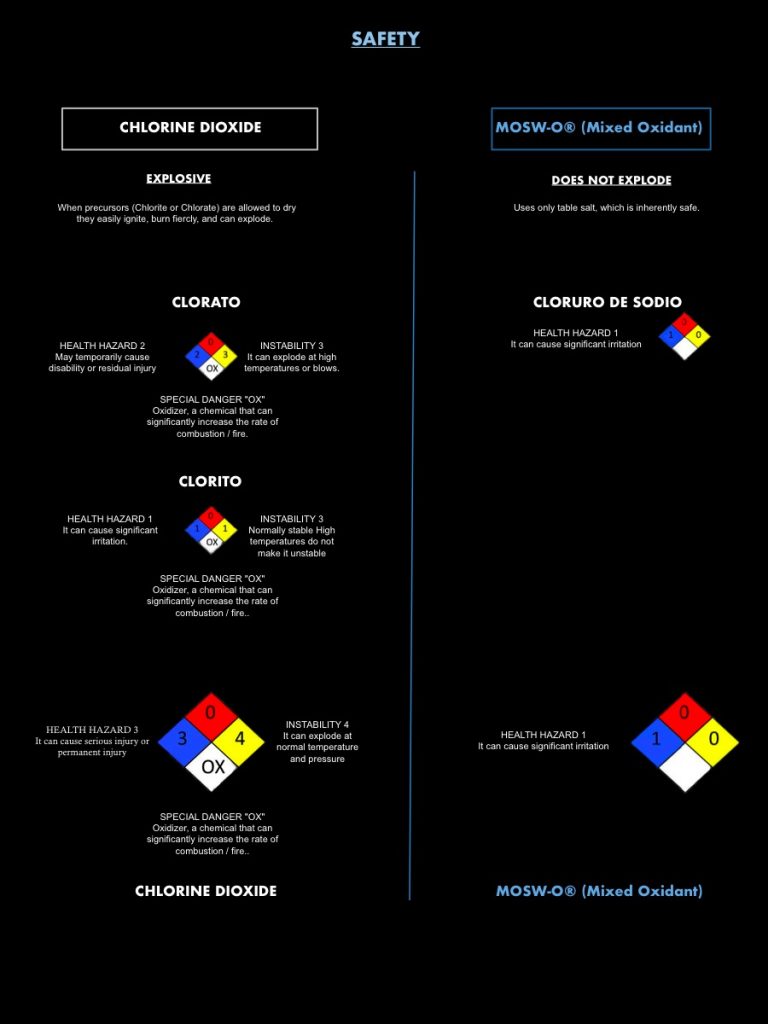

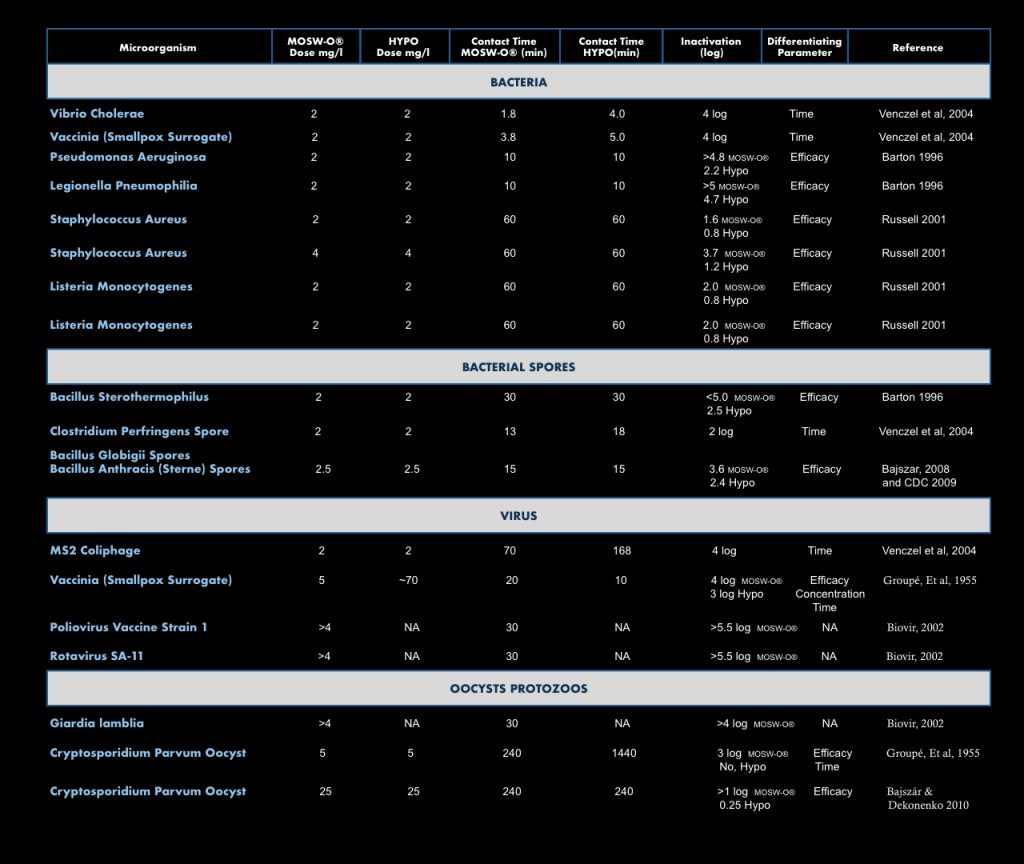

Our mixed oxidants offer many advantages over traditional chlorination, including superior disinfection, longer-lasting residue, biofilm removal, reduced disinfection by-product formation, better taste and odor, and microflocculation. We are able to address other water quality issues that traditional chlorination technologies alone can not address, including total trihalomethane reductions (TTHM) of up to 50%, elimination of biofilm and algae.

A SOLUTION TO YOUR MEASURE

The in situ generation of a disinfectant offers a series of advantages over the transport of chemical products in bulk:

• Improved safety without hazardous chemicals used, stored or produced

• No mixing or dilution since the disinfectant is generated with a constant force

• No degradation of the disinfectant, since it is in the storage

• Elimination of regulatory requirements, including Risk Management Plans (RMP)

• Maintenance of residual chlorine without need of support technology for secondary disinfection

• We produce with a free chlorine concentration (FAC) free of <1%, classified as not dangerous

• Reduction of corrosion since the oxidant does not discharge at normal temperatures

INDIVIDUAL EQUIPMENT – SKID SYSTEMS

Water-On offers two different types of in-situ oxidant generators. Our MOSW-O® mixed oxidant solution systems are designed to achieve maximum disinfection efficiency through the patented cell design, power control and cell geometry. Our sodium hypochlorite systems are designed to provide the absolute lowest and most reliable cost available in the market. Our systems are adapted to any type of installation, for this we have created a wide range of individual models and solutions in Skid in order to meet the market demand, as well as its applications. All our systems comply with the following regulations, among others:

• 4 log EPA certification and 5 log microbial inactivation

• NSF certification for components in contact with drinking water

• European Low Voltage Directive (LVD): 73/23 / EEC (electrical safety)

•CE Compliant

REQUEST ECONOMIC TECHNICAL PROPOSAL

“SALINE ELECTROLYSIS”

MOSW-O®

Specialized Media where you can find information related to Water-On activities and technologies.