EcOSMOSIS®

Osmosis Systems

We offer the unique modular plants and reverse osmosis Osmosis 100% chemical-free World. Designed to treat sea or continental water (well, reservoirs, rivers, lakes, etc …), the EcOsmosis® solution patented by Water-On, is able to inhibit EPS, Biofouling and Incrustation, also incorporating a innovative automatic ultrasonic self-cleaning system for membranes. We develop a growing range of solutions for water treatment, competitive and ecological for municipalities and industry, especially in the areas of desalination and treatment of drinking water and wastewater.

100% Chemical Free

EcOsmosis® operates 100% free of chemicals in all phases of the process. Production of water by reverse osmosis or forward osmosis, is performed without chemical injection at any stage of the production process.

Self-Cleaning of Membranes

EcOsmosis® incorporates an ultrasonic automatic cleaning device for the membranes, which prevents the accumulation of biofilm and the incrustation. This process operates and cleans in a few minutes and can be programmed according to the needs.

Energy Efficiency

Our EcOsmosis® plants are equipped with energy recovery systems. This, together with the self-cleaning system that keeps the membranes constantly clean, allows obtaining the best performance in kW / h per m3 of water produced.

Modular Systems

EcOsmosis® is modular and can be supplied with, or without acoustic insulation, in Skid or inside a container for its location on the outside. Capacities from 250 m3 / day to 35,000 m3 / day

Plug & Play

EcOsmosis® is easily integrated into new installations or in the modernization of pre-existing ones. Install, start and operate. The simplicity of integration is one of its most outstanding virtues.

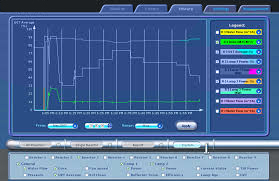

Prediction Software

EcOsmosis® incorporates special software as standard that optimizes its operation and performance. Minimizes and mitigates potential problems in membranes, ultrafiltration or microfiltration.

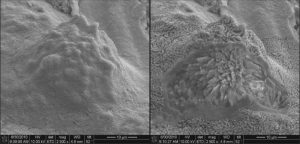

Membranes A-C without inhibitor

Membranes B-D with inhibitor

EcOsmosis® is able of inhibiting the Micro and Macro Biological Contamination. The Inhibitor automatically calculates the electromagnetic energy required according to the quality and volume of the feed water. The energy emitted by the Inhibitor is recycled several times inside the reactor in order to reduce the electrical consumption as much as possible. This allows to reach averages of consumption of 0.04 kWh / m3 of water produced. Undoubtedly, a figure unparalleled in the industry, for the control of biological contamination and therefore the inhibition of EPS and Biofilm.

ADVANTAGES OF BIOLOGICAL INHIBITION SYSTEMS INTEGRATED IN EcOsmosis®

- Water Security:

- Reduces the risk of Biological and Chemical Contamination

- Less Chemicals, Less Energy, More Water Produced:

- Maintains the flow rate lower than the net driving pressure

- Improves membrane recovery properties after a CIP

- Less or no CIP Aggressive is required

- Shorter stop times

- Extends the period of consecutive CIPs

- Longer duration of the membranes (in some cases the life of the membranes has doubled)

The Biological and EPS inhibitor integrated in EcOsmosis® has shown surprising results in many of the osmosis systems it has protected:

-

- Reduction of Differential Pressure up to 32%

- Up to 42% less electrical energy for the same volume of permeate

- Normalization of the rejection of salts at levels above 99% in a stable manner

An easy-to-use interface shows the monitored data in real time, including the actual electromagnetic dose that was delivered, as well as the critical parameters of other auxiliary elements, so you can verify that you are actually delivering the dose you need. Optionally you can include the reporting functions that meet the regulatory requirements. The sophisticated data logging system allows traceability over time of all monitored data. The system complies with the strictest regulatory criteria, including the FDA and the EPA.

The study of the effects of inhibition of metal cations is very important, due to its natural origin in water. EcOsmosis® incorporates a system of inhibition by metal cations that contribute to decrease the nucleation rate of CaCO3. This also promotes its crystallization in the form of aragonite instead of calcite. Even in conditions where calcite would be the preferred form. The metallic cation deposited by our system can act as an accelerator of the heterogeneous nucleation in the volume instead of on the surface.

The system of Inhibition of Mineral Incrustation is able to reduce in 80% the amount of incrustations in the surfaces of the elements to protect in comparison with the systems not treated by the Inhibitor. Reducing up to 74% the level of incrustants formed in the total volume of water + the surface of the elements to be protected. The combination of the effect of Inhibition of the Mineral Incrustation, together with the Biological Inhibition and the EPS present in EcOsmosis®, allow a free operation of chemical products.

The recovery devices integrated in EcOsmosis® consist of an isobaric pressure exchanger and a positive displacement pump combined in a compact unit. It is characterized by a very light and compact design thanks to the fact that the high-pressure booster pump is based on the principle of the vane pump. The vane pumps are fixed displacement pumps in which the flow is proportional to the number of revolutions (rpm) of the motor shaft, which allows control of the flow.

The speed control of the energy recuperator integrated in EcOsmosis ® is carried out by means of a VFD.

The design of the recuperator guarantees the lubrication of the moving parts by the fluid itself. Unlike a centrifugal pump, the pump of the recuperator integrated in our system, produces a similar flow at a given speed regardless of the discharge pressure. All parts are designed to provide a long service life with constant high efficiency and minimum service required.

EcOsmosis® incorporates high pressure pumps designed according to the EN 809 standard for RO applications involving low viscosity corrosive fluids, such as:

• Seawater

• Brackish water

• Waste water (APP W)

The pumps are positive displacement and have axial pistons that move a fixed volume of water in each cycle. The flow rate is proportional to the number of revolutions (rpm) of the input shaft. Unlike centrifugal pumps, they generate the same flow rate at a certain speed, regardless of the discharge pressure. The pumps are supplied by an integrated discharge valve that allows the saltwater to flow from the inlet to the outlet when the pump is not running.

The pumps and energy recovery systems integrated in EcOsmosis® offer an ideal solution for a wide range of users of desalination plants that require reliable and highly efficient systems, both in their hydraulic and energy sectors. Hotels, Residential Sector, Mobile Systems for NGOs and Military, Ships, Maritime Oil & Gas Platforms, Municipalities, Heavy Industry and Food and Beverage, among others, will find in EcOsmosis® the ideal solution to their needs.

ADVANTAGES OF THE AXIAL PUMPS INTEGRATED IN EcOsmosis®:

- No risk of contamination by lubricant:

– The high pressure pumps integrated in EcOsmosis® do not have lubricating oils, these have been replaced by the pumped medium (water), which eliminates the risk of contamination from the pump. - Low maintenance costs:

– Efficient design and stainless steel structure to guarantee an exceptionally long service life. Maintenance intervals of 8,000 hours can be achieved and carried out easily on site thanks to the simple design and the small number of parts. - Lower energy cost:

– The high efficiency of the axial piston design allows to enjoy the minimum energy consumption compared to any similar pump available in the market. - Simple installation:

– More compact and lighter design of the market. The pulsation pressure is extremely low, so no shock absorbers are required.

– All pumps have an integrated discharge valve that facilitates the passage of fluid from the inlet to the outlet when the pump is not in operation.

ADVANTAGES OF ENERGY RECOVERY INTEGRATED IN EcOsmosis®

- All parts of the device are made of materials highly resistant to corrosion, for example, Super duplex.

- Significant energy savings and low specific energy consumption (SEC).

- Require little space since the pump and the pressure exchanger are in a single unit.

- Monitoring without the need for high pressure flow meters

- Designed to avoid overshoot / overflow

- One of the smallest and lightest energy recovery devices on the market

- Few Components

- Without high cost high pressure mechanical seal

- Possibility of simple modular services

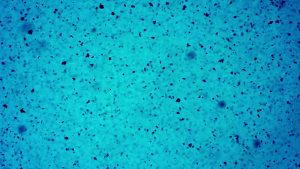

OsmoSonic® is a programmable ultrasonic cleaning system patented by Water-On that allows the automatic cleaning of the membranes and the pressure tubes taking advantage of the kinetics of inhibition of biological and mineral incrustations relatively slow of EcOsmosis®. Once OsmoSonic® performs the function of agitation and cleaning, the resulting concentrate is eliminated and discharged by means of a flux with permeate water or even with water for feeding the plant.

ADVANTAGES OF THE OsmoSonic® SYSTEM:

- The design of OsmoSonic® is based on a simple structure coupled to the pressure vessels

- Replaces the addition of chemicals to avoid fouling and cleaning the membranes

- Does not require prolonged plant shutdowns for membrane cleaning, unlike traditional reverse osmosis systems

- Reduced energy consumption

- Ceramic and polyamide materials that are not affected by corrosion or heat

EcOsmosis® incorporates its own, reliable and innovative software that measures and monitors the evolution and development of incrustations of all membrane systems of Reverse Osmosis (RO), Nanofiltration (NF), Ultrafiltration (UF) and Microfiltration (MF) in Brackish water and Seawater Treatment Plants.

The EcOsmosis® software is different to any standardization program available from the membrane manufacturers, since it is not based on the performance trend, but on the measurement of its true parameters and the potential for real-time embedding. Monitoring allows users to continually check the operating performance of the system and detect the development of any tendency of contamination or deterioration of the membranes long before the adverse symptoms that produce a significant or irreversible loss of performance occur. The software does not require additional data collection or system maintenance.

EcOsmosis® allows a significant reduction of downtime, maintenance and operation costs of the plant, while ensuring that it produces the quantity and quality of design water with maximum efficiency and availability.

ADVANTAGES OF THE EcOSmosis® CONTROL SOFTWARE:

- Significantly reduces plant downtime

- Significant reduction in O & M costs

- Significantly reduces maintenance work on the plant

- Significant improvement of plant data management

- Significantly reduces the potential for soiling

APPLICATIONS

- Brackish Water Plants

- Sea Water Plants

RELIABLE AND EFFECTIVE TO ANY CHALLENGE

Our systems of osmosis and brine recovery respond to an increasing concern for the sustainability of the processes of obtaining drinking water and the mitigation of reject waters. The technologies offered by Water-On are ideal to purify both water from the sea and well or continental waters. With solutions tailored to each end user, we can offer sustainability, reliability, safety and profitability to sectors as large as Municipalities, Tourist Centers, Food Industry, Heavy Industry and Agriculture …, among others.

EACH SOURCE OF WATER IS UNIQUE

Cada fuente de agua tiene sus particularidades físico-químicas. La versatilidad de nuestra tecnología EcOsmosis® permite adaptar el tratamiento del agua a dichas particularidades. Tanto para afrontar problemas de contaminación marina donde se detecten hidrocarburos, materia orgánica, sales, metales pesados…., como para afrontar dicha problemática en aguas de pozos continentales con exceso de iones o contaminantes. Nuestra tecnología de Ósmosis es la mejor solución para la obtención de agua potable de calidad.

EQUIPMENT IN SKID – CONTAINERIZED SOLUTIONS

Our reverse osmosis systems are designed to adapt to the needs of treatment and production of drinking water in medium and large facilities. With workflows from 250 m3 / day to 35,000 m3 / day. We cover with it the greater part of the demand for Reverse Osmosis existing in the market. All our systems comply, among others, with the regulations and provisions that we relate below.

Compliance with Directives and Regulations:

FDA CFR 21 Parts 170 to 199 for contact with food.

Cables and Electricity:

- CEI 20-13 IEC 60502 CEI UNEL 35375-35377; CEI 20-22 II CEI EN 60332-1-2 CEI EN 50267-2-1; VDE 0472 / VDE 0295 / VDE 0290 VDE 0281 / VDE0245 /; EIA RS 485

Pressure vessels:

- 2014/68/UE

Pumps and VDFs:

- 2014/35/EU ; 2009/125/EC ; 2011/65/EU ; 2006/42/EC ; 2014/30/EU; EN 1.4462/UNS S31803 ; EN1.4410/UNS S32750 ; Pumps Available with certificates ATEX: Category 2, zone 1 or Category 3, zone 2. For others, consult.

Instrumentation:

- 2014/34/EU ; 2014/30/EU ; 2011/65/EU ; 2014/68/EU

Valves and Valve Control:

- 2014/68/EU ; 9/68/CEE ; 89/336/CEE ; 89/392/CEE ; 90/336/CEE ; 97/23/C ; 72/23/CEE

REQUEST TECHNICAL-ECONOMIC PROPOSAL

“OSMOSIS”

EcOsmosis®

Specialized Media where you can find information related to Water-On activities and technologies.